Using coupling agents as reinforcing and filling agents for rubber is generally aimed at improving the strength of the material. There are research reports that using silane coupling agents can not only significantly improve physical and mechanical properties, but also improve the thermal aging performance of materials; Titanate coupling agents have a negative effect on aging performance [2]. Therefore, this experiment envisions using silane coupling agents to form a film on the surface of the filler to block the catalytic oxidation of rubber hydrocarbons by the variable valence metal ions contained in clay particles, in order to improve the thermal oxidative aging performance of clay adhesive.

1 Experimental section

1.1 Raw materials

Rubber: Natural rubber concentrated latex, with a dry rubber mass fraction of 56.7%. Origin: Experimental Farm of Chinese Academy of Agricultural Sciences. Clay: Fine suspension of clay particles, with a solid mass fraction of 21.7%. Origin: Nanhua Farm, Guangdong Province.

Chemical reagents: (Other are commercially available industrial grade products)

Silane coupling agent KH-550 (r-aminopropyltriethoxysilane), industrial grade, produced by Chiye Organic Silicon Materials (Shanghai) Co., Ltd.

1.2 Sample preparation and testing of clay adhesive

See literature.

2 Results and Discussion

2.1 The anti thermal oxidative aging effect of silane coupling agents

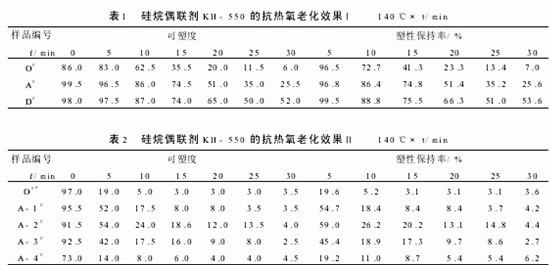

Table 1 shows the changes in plasticity and plastic retention rate with aging time of clay adhesive blank sample (O #), clay adhesive with the addition of 1 part silane coupling agent KH-550 (A #) and 1 part anti-aging agent (D #). From the results in Table 1, it can be seen that the silane coupling agent has a significant protective effect on the thermal oxidative aging of clay adhesive.

2.2 Effect of Silane Coupling Agent Dosage

To further investigate the effect of the uncoupling agent, different amounts of KH-550 were added to the clay adhesive. The prepared clay adhesive samples were exposed to air for 2 months, and then the plasticity and plastic retention rate of the samples were tested as a function of thermal aging time. The test results are shown in Table 2. O #: Blank comparison sample; A-1 #: Add 0.5 parts of KH-550 clay adhesive; A-2 #: Add 1.0 part of KH-550 clay adhesive; A-3 #: Add 1.5 parts of KH-550 clay adhesive; A-4 #: Add 2.0 parts of KH-550 clay adhesive. The addition amount is based on the mass ratio of clay.

According to the data in the table, in Group A formula, the addition of 1.0 part silane coupling agent had the best effect. After 10 minutes of thermal aging, the plasticity of the blank sample without coupling agent was close to the lowest value. However, the plasticity of the sample with 0.5 part, 1.5 part, and 2.0 part coupling agent was lower than that of the sample with 1.0 part coupling agent. This is because when one part of the coupling agent is added, a relatively complete single-molecule layer coating film can be formed for the clay particles, which precisely blocks the action of metal elements in the clay particles on rubber hydrocarbons. Many studies have reported that when one part of the coupling agent is added (to the mass ratio of the filler), the coupling agent has the best effect. The amount of coupling agent used is too small to form a complete film and cannot play the expected role. However, excessive coupling agents will have a negative effect, resulting in a decrease in plasticity.

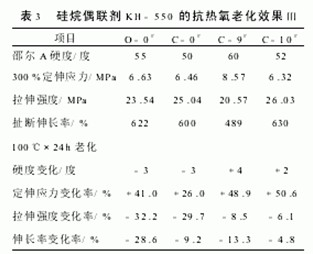

2.3 Synergistic effect of silane coupling agent and anti-aging agent

To compare the effect of KH-550 on the physical and mechanical properties of vulcanized rubber, the samples in Table 3 are C-0 #: add 1 part of KH-550 clay vulcanized rubber; O-0 #: Vulcanized rubber of blank sample; C-9 #: Clay vulcanized rubber with one part of anti-aging agent added; C-10 #: Add 1 part KH-550 and 1 part anti-aging agent at the same time. The physical and mechanical properties of the test sample before and after aging are shown in Table 3.

From the results in the table, it can be seen that C-0 # with the addition of silane coupling agent has the highest comprehensive performance among the three samples before aging compared to O-0 # and C-9 #, which also confirms that the coupling agent can improve the strength of rubber materials. The aging data of C-0 # is equivalent to that of C-9 #, while the blank sample O-0 # without coupling agents and anti-aging agents shows a significant decrease in performance after aging. This indicates that the application of silane coupling agent in clay adhesive can not only greatly improve the strength of the material, but also play a role in preventing thermal oxidative aging. C-10 # has the best comprehensive performance among the four samples, indicating a good synergistic effect between silane coupling agent KH-550 and anti-aging agent.

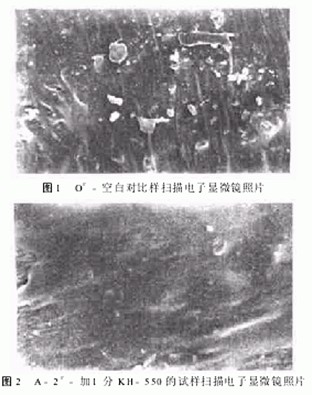

2.4 Electron microscopy analysis

Figures 1 and 2 show a set of scanning electron microscope photos of uncured clay adhesive. Figure 1 shows blank control sample O #, and Figure 2 shows sample A-2 # with one part of silane coupling agent KH-550 added.

Comparing the two photos, it can be seen that on the cross-section of the O # sample, the boundary between the clay particles and the rubber material can be clearly seen, that is, the clay particles are only contained within the rubber hydrocarbon and have no binding force with the rubber hydrocarbon. On the photo of sample A-2 #, it can be seen that the cross-section is relatively smooth. Due to the addition of silane coupling agent, the bonding between clay particles and rubber hydrocarbons is good, and there is no obvious boundary between clay particles and rubber material on the cross-section. That is to say, due to the bonding between the two active groups of silane coupling agent and the filler clay particles and rubber hydrocarbons, a bonding force is generated between the clay particles and the rubber material, resulting in a smooth and flat cross-section, thus improving the physical and mechanical properties of the material.

3 Conclusion

Applying silane coupling agent KH-550 to clay adhesive can not only greatly improve the strength of the material, but also have a significant anti thermal aging effect. At the same time, it has a good synergistic effect with anti-aging agents. The optimal dosage is 1 part - to clay mass ratio.

add wechat

add wechat

24 hours tle021-58997516

Mobi13321881626

Copyright © 2002-2022 ChiYe (shanghai) Co,ltd Address:Shanghai in China Case Number:沪ICP备14048717号-1 Siemap